Productivity

Leverage our technology and data insights for exponential increase in operational efficiency.

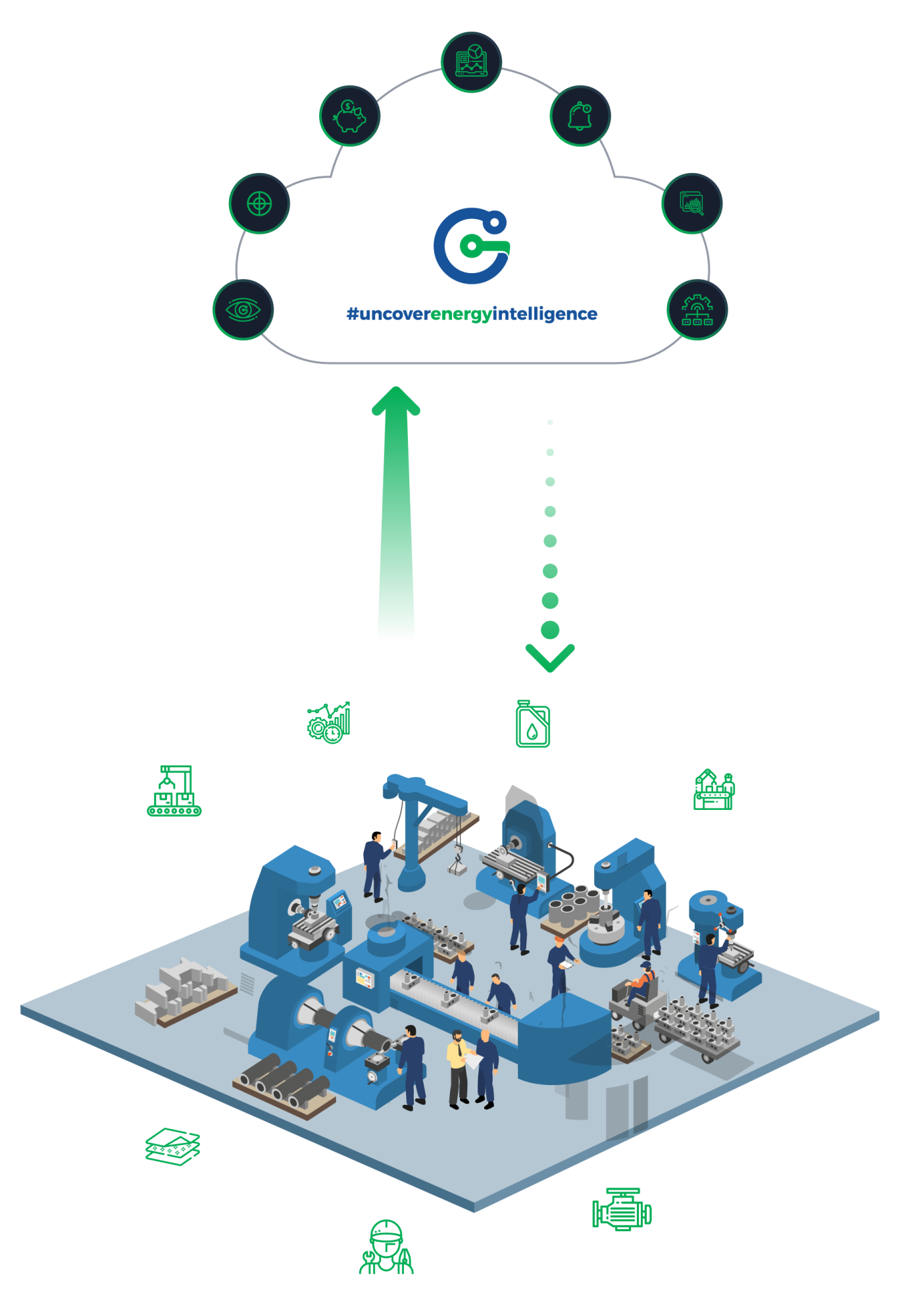

Overview

Operational productivity is a powerful metric that measures the overall efficiency of manufacturing processes. It takes into account three critical factors: availability, performance, and quality. Technology can significantly enhance the manufacturing productivity by Seamless monitoring, predictive analytics, and machine learning algorithms, Our suite of productivity tools equips businesses with the necessary resources and real-time insights to achieve optimal process efficiency, paving the way towards high standard of operational excellence.

Benefits

Features

-

Easily track OEE metrics and performance indicators with our user-friendly drag & drop dashboard. Get actionable insights and create instant reports

-

Get detailed analysis of equipment & operator performance to identify bottlenecks, track downtime, and ensure equipment effectiveness

-

Manage and analyze quality data to identify and reduce defects, scrap, and rework.

-

Integrate with production planning tools to provide real-time data on resource availability and performance.

-

Integrate with other manufacturing systems such as ERP and MES to gain a comprehensive view of the production process

Our Process

01Capture

Gather real-time data on equipment, operators, and processes to gain visibility into your manufacturing process. Identify areas of low OEE and set targets to improve efficiency

02Optimize

Take action to maximize production, reduce downtime, and eliminate quality issues. Implement a comprehensive OEE optimization plan that incorporates operator training, preventive maintenance, and continuous improvement initiatives

03Scale

Leverage advanced analytics and machine learning algorithms to capture data at a granular level and expand OEE improvements to multiple production lines and facilities

04Sustain

Monitor OEE metrics and track progress using real-time insights to sustain ongoing improvements and address inefficiencies as they arise

05Achieve

Attain a high standard of operational excellence by continuously improving OEE and maximizing productivity while maintaining product quality and minimizing waste

Safety & Reliability

Predict potential breakdowns and reduce risk exposure to assets and employees with advanced analytics.

Energy Efficiency

Maximize your energy efficiency and minimize your carbon footprint with our innovative EMS solutions.