Textile

Achieve Energy and Water Efficiency in Operations

Transform textile operations by optimizing resource management, reducing water usage, and cutting energy costs to boost sustainability and operational performance.

Platform Capabilities

Streamlining Resource Utilization

Energy Accounting

Monitor and manage electrical, thermal, and solar energy consumption across weaving, dyeing, and finishing processes to enhance efficiency, reduce costs, and meet sustainability goals.

Pattern Recognition

Optimize energy usage across spinning, weaving, dyeing, preparatory, blue room, and humidification plants by detecting consumption trends and AI-powered shift recommendations for maximum efficiency.

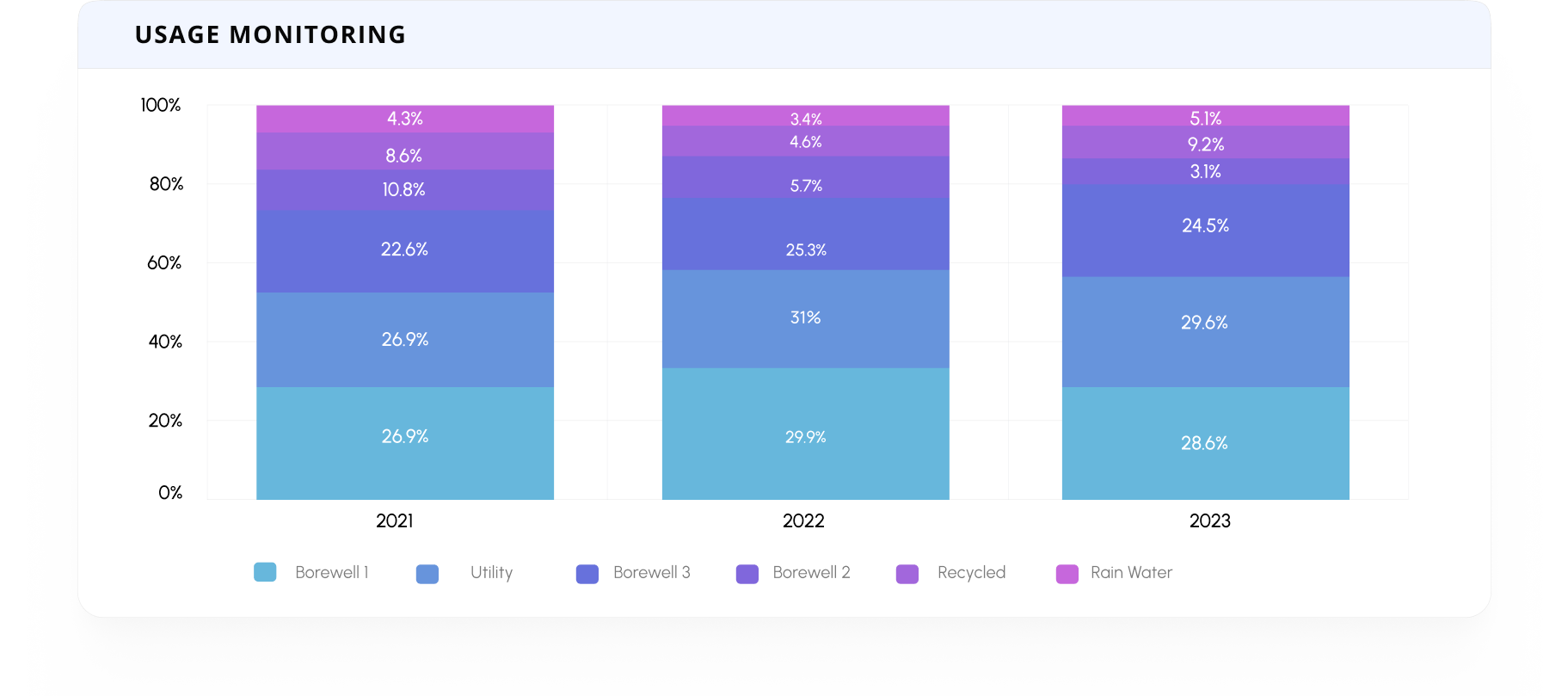

Usage Monitoring

Track UKG variance, per-count energy consumption, and kWh per 1,000 spindles across processes, ensuring precise resource allocation and operational efficiency in textile manufacturing.

Overall Equipment Effectiveness

Evaluate per-count efficiency across production lines, identifying bottlenecks and optimizing machine utilization to maximize throughput and minimize energy waste in textile manufacturing.

Regulatory Compliance Monitoring

Achieve seamless compliance with ISO 50001, BRSR, and GHG Protocol through automated monitoring, ensuring sustainable manufacturing operations.

Trusted By

Solutions

AI-Powered Insights for Sustainable Growth

Energy

Balance

Identify and implement specific energy-saving actions, cutting costs and balancing usage.

Water

Balance

Target and reduce excess usage for cost-effective, sustainable water practices.

Asset Lifecycle

optimization

Drive significant cost savings and optimize asset performance throughout their lifecycle.

Net Zero Transition

Program

Fast-track to net zero with actionable insights and complete emissions visibility.

Enterprise Data

Intelligence

Integrate our data into your systems, BI platforms, and custom models via a robust interface.